Additional benefits of firestop products in healthcare facilities

When it comes to safety, hospitals are uniquely challenging environments.

Firstly, many occupants will have mobility issues, meaning that that evacuation times must be maximized in case of fire. Secondly, as mission-critical facilities, hospitals should remain largely operational after such an event. Thirdly, airflow passing through the facility daily should be reduced to limit the transmission of viruses and infection. Hilti passive fire solutions can help fulfil all of these special design needs.

Fire compartmentation must use tested firestop systems and comply with Building Codes and Regulations

Compartmentation sub-divides a building into smaller units in order to hinder the spread of fire from one zone to another.

When it comes to hospitals, globally or nationally used hospital guidelines recommend that the following occupancies / function areas should form separate fire compartments, with a fire rating of at least 60 minutes:

- Patient room areas

- Kitchen and restaurant

- Laundry

- Surgery areas

- Laboratory areas, etc.

On floors containing patient rooms, another level of protection is required: each floor should be subdivided into at least two compartments. If a fire occurs in one compartment, patients are then able to take refuge in the other one or use the respite to find and use dedicated escape routes.

Hilti has over 30 years experience in providing internationally tested and approved firestop systems for a wide range of mechanical, electrical and mixed penetrations applications. These can be used across an entire hospital project to achieve an efficient compartmentation.

For further reading on Firestop in Healthcare

Adapted firestop solutions improve airflow control and reduce infection transmission risk

Penetrations for services between patient rooms can represent a source of airborne bacteria transmission or Healthcare Associated Infections (HAI). Airflow from one space to another occurs through cracks or gaps in walls, ceilings, floors and around doors.

Firestop products play a pivotal role in airflow control, which is especially critical in surgery rooms, intensive care units and isolation rooms. Openings in walls and floors must be tightly sealed to help prevent air leakage and maintain the airflow towards one direction. Many design manuals for hospitals and clinics also advise reducing airflow at penetrations, such as plumbing, sanitary or electrical cabling, along with gas, utility and network communication outlets and gaps in doors or window joints. Doing this reduces infection transmission between the rooms and creates a cleaner environment.

For electrical penetrations, the Firestop Sleeve is the optimal solution in the Hilti product portfolio. In the next section of this article, we’ll show you why it is a smart choice for use in hospital environments.

Firestop Sleeve installed in hospital project

How to select the best firestop products for airflow control in hospital facilities

There are several methods of measuring the air leakage of construction products. EN 1026 is an internationally recognized standard which defines a conventional method to determine the air permeability of construction elements when submitted to positive or negative test pressures. The results allow a better understanding of a product’s suitability for specific applications.

Hospitals operate at differing pressure ranges that should remain stable, depending on a room’s function and the activity performed within it. For example, there should be a negative pressure in clinical areas where patients with airborne infectious illnesses are staying. Conversely, there needs to be positive pressure in protective rooms for certain patients (such as those with a compromised immune system).

With positive pressure, air movement is going out of a room, largely preventing “dirty” air from entering. With negative pressure, “dirty air” is retained within a room, helping to prevent it from contaminating “clean” air elsewhere. A room’s static-pressurization value is wholly dependent upon the differential airflow and the room’s leakage rate.

A sequence of EN 1026 testing at an accredited third-party institute “ift Rosenheim GmbH”, measured the air tightness of the Hilti Firestop Sleeve. A series of pressure steps were examined to cover a broad range of applications. The tests also covered a variety of cable fill ratios, from empty (0%) to 100% visual fill, to represent the increasing number of cables as facilities are scaled up. The following graph shows one of the several test series’ results and describes the air tightness behavior of the Hilti Firestop Sleeve at different fill rates (at 10 Pa)

Testing compared 4” Firestop Sleeve air tightness performance at different fill rates, device installed according to manufacturer’s Instruction for Use.

Cables used: CAT6 cables (OD=6mm), end of cables sealed;

Fill rate 0% = 0 cables (blank); Fill rate 20% = 28 cables; Fill rate 40% = 57 cables; Fill rate 60% = 86 cables; Fill rate 100% = 142 cables;

Leakage measured @ 21 °C; 52 - 57% RH, @10 Pa and tested according to EN 1026 – test reports available upon request;

Airflow in [m³/h] measured for over- and under pressure, chart displays average values

Air leakage for Hilti Firestop Sleeve fill acc. to EN 1026 – third-party test reports from December 2016

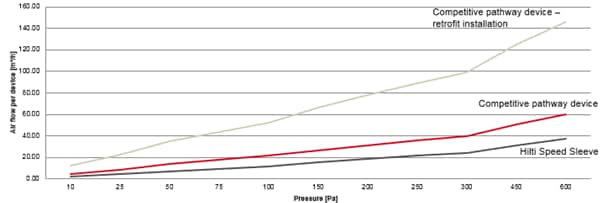

Testing of the Firestop Sleeve at different pressure differentials shows a high performance compared to competing products.

Air tightness Hilti Speed Sleeve vs. Competitive Pathway Device

Testing 4” Firestop cable device with 40% cable fill; installed acc. to manufacturer Instruction for Use 40% cable fill = 57x CAT6 cables (OD=6mm), end of cables sealed;

Leakage measured @ 21 °C; 52 - 57% RH and tested according to EN 1026 – test reports available upon request;

Airflow in [m³/h] measured for over- and under-pressure, chart displays average values;

Air leakage for firestop Sleeve at 40% fill acc. EN 1026 – third-party test reports from December 2016

Firestop Sleeve technology results in superior airflow control

The Hilti Firestop Sleeve’s superior air tightness is a result of its twist-design. When the inner fabric liner twists closed, it wraps around an extended length of the cables, resulting in excellent airflow control.

Neutron ray imaging at Paul Scherrer Institute in Switzerland allows us to look inside leading firestop cable pathways and show that the Firestop Sleeve has optimal airflow control, with a performance of less than 4ml/s of air transmission.

Hilti Speed Sleeve CFS-SL with closing mechanism to increase air tightness – third-party CFD simulation by Paul Scherrer Institute from June 2016

The considerable differences in airflow performance between the sealing technologies of various firestop products can substantially impact a facility’s infection transmission rate. So, if you want to help ensure you have the correct airflow control where it is needed, contact us today for more information.

Contact a Hilti engineer for support on Firestopping

See how Hilti's solutions were able to help protect frontline workers during the COVID-19 pandemic

Sources

Characteristics of Healthcare-Associated Infections Contributing to Unexpected In-Hospital Deaths (2010) https://www.ncbi.nlm.nih.gov/pmc/articles/PMC3528178/

Hilti Firestop Whitepaper, Increase your data center energy efficiency by choosing the right firestop products (2017)

ASHRAE HVAC Design Manual for Hospitals and Clinic