Solutions for direct product installation

Wood has been used as a building material in construction for many years. Approximately 20 years ago, mass timber was born in Austria/Southern Germany. This is the collective term for a set of industrially produced wood elements that not only offer static characteristics comparable to concrete and steel, but also perform well under fire conditions. The most notable members of the mass timber family – are structural or engineered wood – include cross-laminated timber (CLT) and glue-laminated timber (Glulam, GLT).

The last years, production of engineered wood is growing steeply across the globe, particularly in key regions like in Central Europe and the Nordic Region. Therefore, mass timber is becoming more and more relevant.

Nevertheless, wood construction faces challenges due to high levels of regulatory burdens, primarily related to firestopping: mass timber is still a combustible material. Replicating concrete or steel designs for wood has also turned out, in some instances, not to be as cost-efficient. However, when building system is tailored to structural wood, and not a concrete/steel replicant, as shown in some recent projects, present a much better building cost position.

Mass timber construction with CLT, Glulam and others, present a new set of in-depth researched base materials enabling significant regulatory changes across the globe that boost wood as a building material. This goes hand-in-hand with extending the use of wood beyond today’s main market (single-family residential housing projects with light-duty framing structures) into mid-rise or high-rise commercial buildings. Alongside regulatory changes, we are also seeing multiple government initiatives to push wood construction, given its positive characteristic of capturing CO2 for the lifetime of a building.

These relatively new elements have enabled new applications for mass timber, notably for low to mid rise buildings, because of the multiple benefits they offer.

CLT has a high load-bearing capacity, high fire resistance compared to other wood based materials and is light in weight. It also burns slowly and, in case of fire, will never burn down completely in a normal fire situation because of the charring of the wood acts as a natural fire barrier. However, this alone is not enough to help ensure occupants’ safety as CLT is a more onerous base material when comparing to typical building materials like concrete when it comes to fire as the CLT being wood is combustible and chars under fire.

Passive fire protection is a vital element of wood construction

Passive fire protection is vital for creating a safer and code-compliant building. Compartmentation is a general safety requirement that applies to all buildings, depending on their height and use class, regardless of their base material. The most common issue in a fire compartment is when building services need to pass through a separation floor or wall. This requires adequate passive fire protection measures to seal the openings. During a fire, an important difference between concrete or drywall and wood needs to be considered: wood is combustible. Mass timber such as CLT chars at about 0.7 mm per minute. To fill the gap caused by the burning of the wood and to prevent the spread of smoke and fire, all openings in fire-rated walls and floors must be sealed with firestop products that meet the desired requirements, eg. Product with intumescence property which expands when exposed to fire.

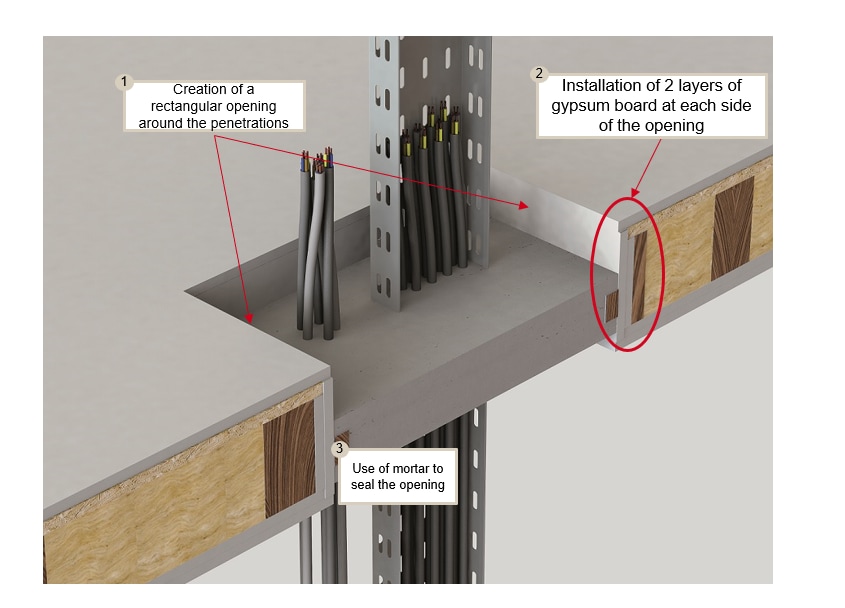

With the larger number of CLT relevant buildings in Europe, the typical approach in the absence of an approved solution for firestopping in timber, mortar has become the default choice. Until now, firestopping a through-penetration application was a 3-step solution:

This method of firestopping significantly reduces productivity because installing and curing mortar takes time. It also detracts from the aesthetic pleasure of the exposed wood and, last but not least, off-site construction is not possible.

Extensive fire testing for compliant solutions

Over the last couple of years, Hilti has focused on performing extensive fire testing (with third-party accredited testing institutes) of firestop products on timber floors and walls particularly with the range of advanced preformed products. The impressive test results have not only proved the uncompromised performance of Hilti firestop products on wood but have also paved the way towards the first official approvals covering such a broad application range. With our extensive testing in numerous CLT base material variations, Hilti's firestop solutions can apply to larger project and CLT types. The use of a compliant product range and system significantly increases the efficiency during the planning process.

Direct installation of firestop products on wood- no formwork or mortar required

Sophisticated fire tests have proven the performance of our products for a broad range of firestop application in CLT and Glulam elements.

Multiple floor and wall systems have been successfully tested for FRL -/60/60 & FRL -/90/90.

Our dry solutions, with the use of preformed products, can be directly installed in wood and do not involve gypsum board or mortar. This means that firestop can be installed in prefabricated timber elements before they leave the factory – helping to reduce construction time on site by as much as half.

Wastewater and roof drainage

Sanitary applications (Hot and cold water pipes)

Electrical applications

Mixes penetrations/large openings

Hilti has been a trusted firestop partner for more than 30 years, providing internationally tested and approved firestop systems for a wide range of applications. By expanding our testing to firestop applications in wood, we support our customers in achieving efficient compartmentation and legally compliant and safe timber buildings. Hilti engineers are ready to take on project based firestop design challenge, working with builder and sub-contractors to provide compliant solutions for the project

For additional support, please comment below or reach out to us through our Firestop Consulting Service